The Duntov team represents three generations of Corvette racers going back sixty years. We started Corvette racing at the top with Corvette Grand Sport 003 that the founder of this company bought from John Mecom in December 1964, after AJ Foyt drove the car at the Nassau Speedweeks. Since then, our family has won eight National Championships, raced on three continents, and two of the three generations are still racing today. The parts and services offered here are the result of lessons learned from all that racing and all those millions of dollars pushing the envelope.

We have changed the presentation of our racing parts. We no longer use the shopping cart click and buy format we have used for the past twenty years and still do today for our streetcar parts. We have learned a better way to get the right parts to racers is through interaction. Check the sections below and reach out to us for the full range of options available for brakes, steering, suspension, set up, etc. It is better way to make sure we are supplying the right product to fit your needs. [email protected]

The parts pictures below are of this car as it came off the track after its last win.

Brakes

Nowhere is money better invested in a vintage Corvette racecar than in its brakes. The new brake pad compounds offer incredible stopping power, which of course means more heat that has to be dissipated.

We have these pads in stock in both the standard thickness and double thickness. The thicker pads better insulate the brake fluid from the red-hot rotors, and of course require wider calipers. All of our racing calipers come with titanium pistons to keep that heat away from the brake fluid.

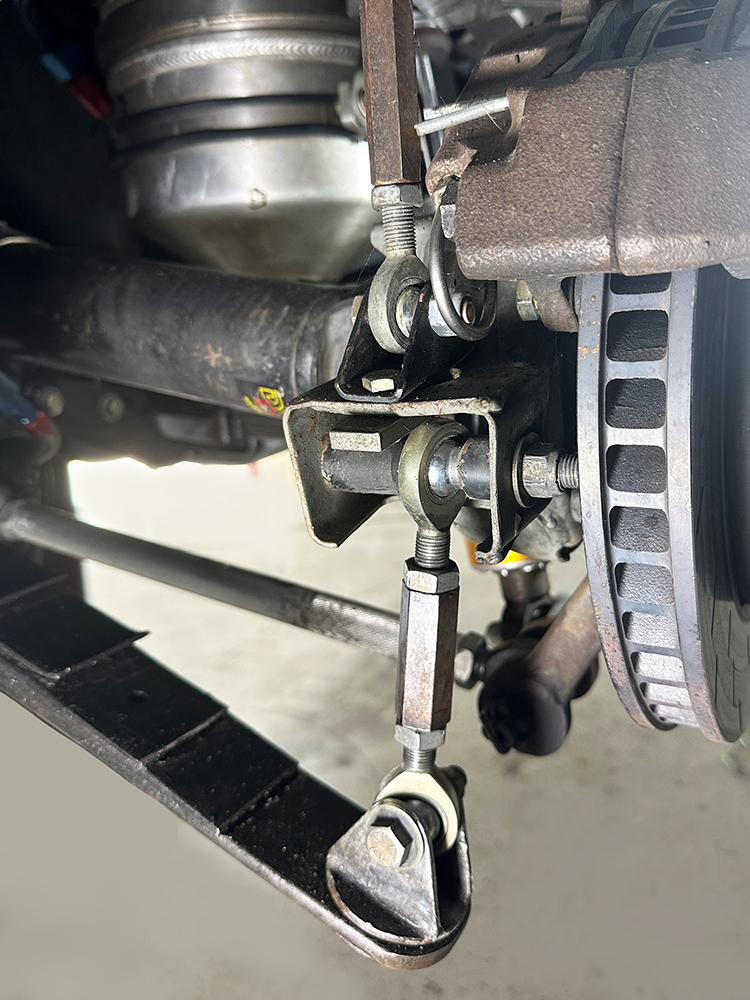

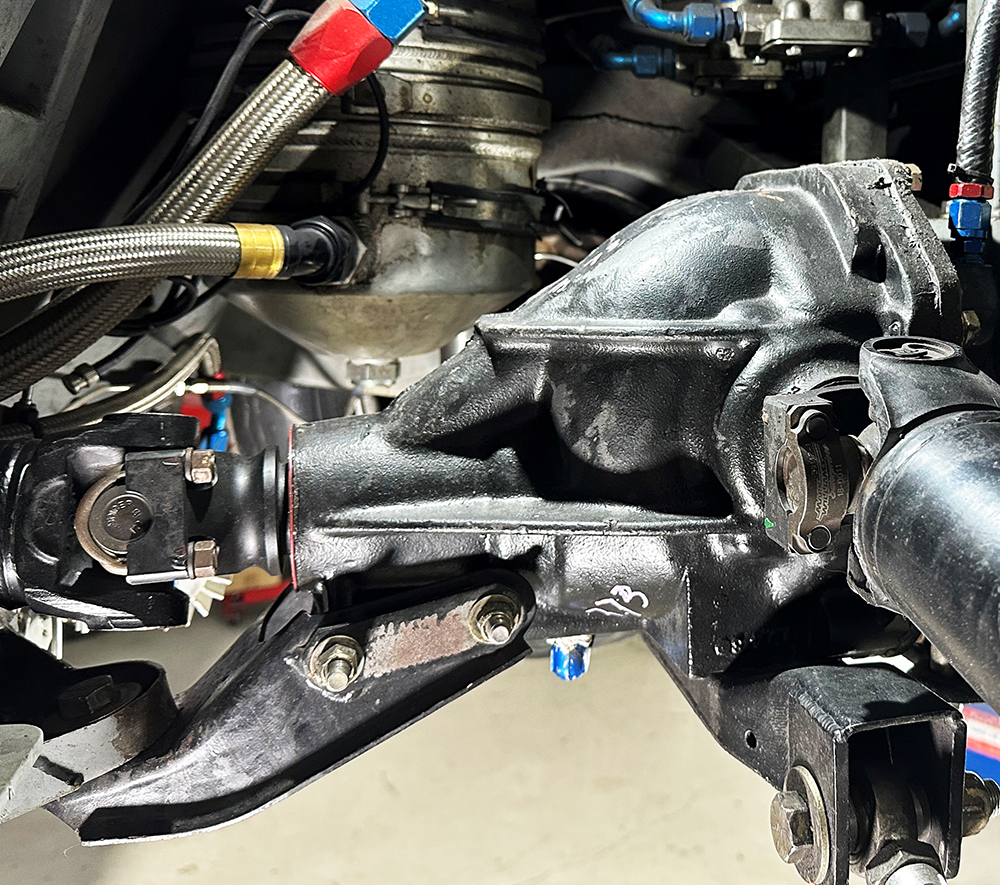

We also offer the reverse caliper mount assemblies as shown here that allow better air ducting among other things. Email for a complete list of brake options for your vintage racing Corvette.

Chassis Stiffness

As you may have seen written elsewhere in this website, chassis stiffness is by far the most important element in handling. Tadge Juechter, Corvette’s Executive Chief Engineer, had this to say on the subject:

“85 percent of handling is chassis stiffness; everything else – the shocks, springs, sway bars, etc, together adds up to only 15%.”

These frames need a lot of work before springs and shocks can do their magic.

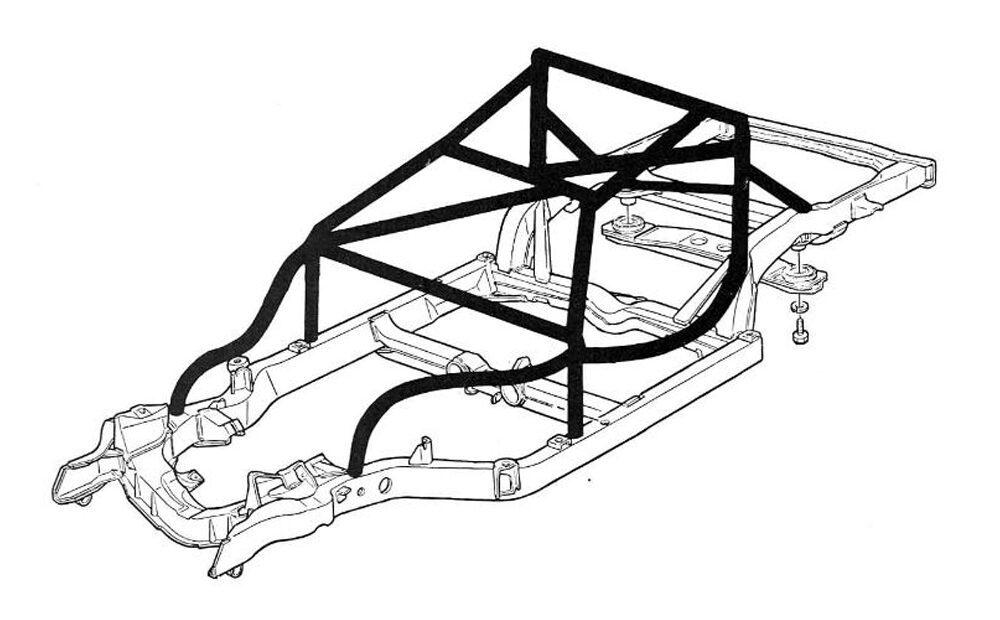

This roll cage illustration is from the early 70’s Chevy Power Book, and represents the bare minimum in both stiffness and driver protection. We have learned that by putting a lot more into the frame preparation and cage design, we get a lot better result.

Steering

We were among the last to embrace power steering in a vintage racing Corvette, but it is definitely the way to go, no matter how strong you are! These cars want a lot of caster – as much as you can handle. The more caster, the harder it is to turn the wheel, so anything more than about 3 degrees becomes a problem after a long stint. With our power steering system, you can run 7 degrees of caster, which the car really likes.

Shown at the left is our adjustable bump steer blocks, an absolute necessity to calm down that vintage Corvette.

Suspension

This conversation has to start with: “How stiff is your frame?” When the answer is as strong as any, then every little change in spring rate, sway bars and shock settings will make a big difference in the balance of the car.

Adjustable sway bars allow you to maximize your handling when the tires start to go away. We have all the parts you will need to help your car handle better whether or not you are trying to set lap records. We know how to make the car fun to drive.

Notice the armor-plated trailing arm. The stock arm flexes under acceleration, changing the rear toe and upsetting the handling. Our trailing arms don’t bend.

Wheels

We developed these period correct Duntov wheels and have run them for 15-years. Being modular, they work with every caliper option we offer. There is not a lighter wheel of comparable size and strength on the market.

They can be ordered in 15- or 16-inch diameters in widths as wide as 16-inches. Below is our Greenwood car with ten-inch fronts and sixteen-inch-wide rears.

The rims are polished aluminum, and the hubs can be specified in either black, gold or polished aluminum.

Email Alan if you have a non-standard application so that we determine the back spacing you need to clear your calipers and fender flares.

Body

We make our own fiberglass parts and bodies in-house. We have molds for the original Corvette Grand Sport and the Greenwood Widebody.

We also make L88 flares and headlight kits for C3 Corvettes, as well C-2 and C3 Corvette acrylic windshields for vintage racing.

If you have a need for custom fiberglass in any virtually configuration, let us know. Below is a C2 ground effects kit we built for a client who wanted to go very fast. It was designed to evacuate the air from under the car by directing it through slots in the rear valence panel.

Differentials & Driveline

We have been building our own Corvette racing differentials for over forty years, and lately we have been shipping them to Corvette racers around the world. Depending on the type of racing you are doing, the power and tire patch you are working with, we have options for you.

The original Dana Corvette differential that was introduced in 1963 was designed handle up to 400 hp and deliver it to tire patches that were about 4-inches wide. In today’s vintage racing, that same design is often tasked to transfer twice that power to almost three times the tire patch.

The ring and pinions of all our racing differentials are REM coated and the ring gear bolts safety wired. The preload setup is specific to racing applications.

The diameter of the differential stub axles and the rear wheel spindles are limiting factors that can only be overcome with parts made from superior materials. We can supply those parts made from materials that will handle these extreme loads.

The differential does not have to be the weak link in your driveline.

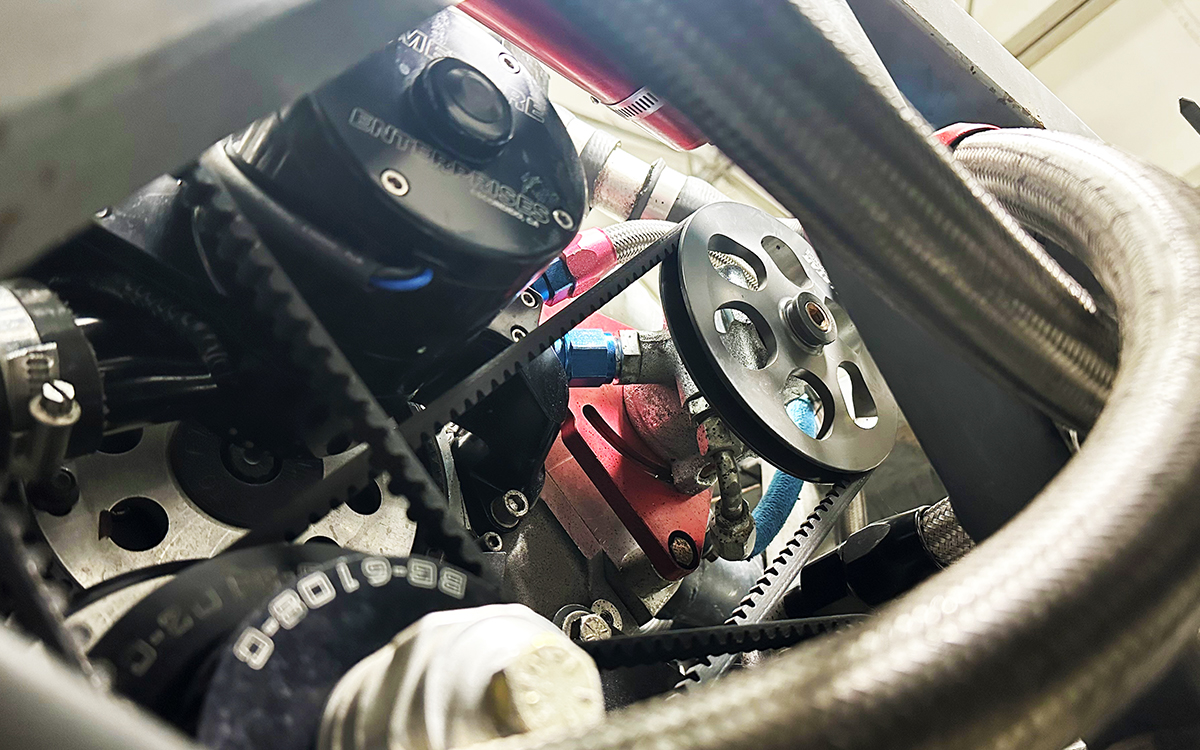

Power

We build our own engines in house, and have been since 1980. The technology has changed dramatically since then, but the basics remain the same: Racing engines are expensive!

Often spending money on boosting engine performance gives the least return on investment measured by lap time. Most lap time improvements result from improved handling and its effect on driver confidence.

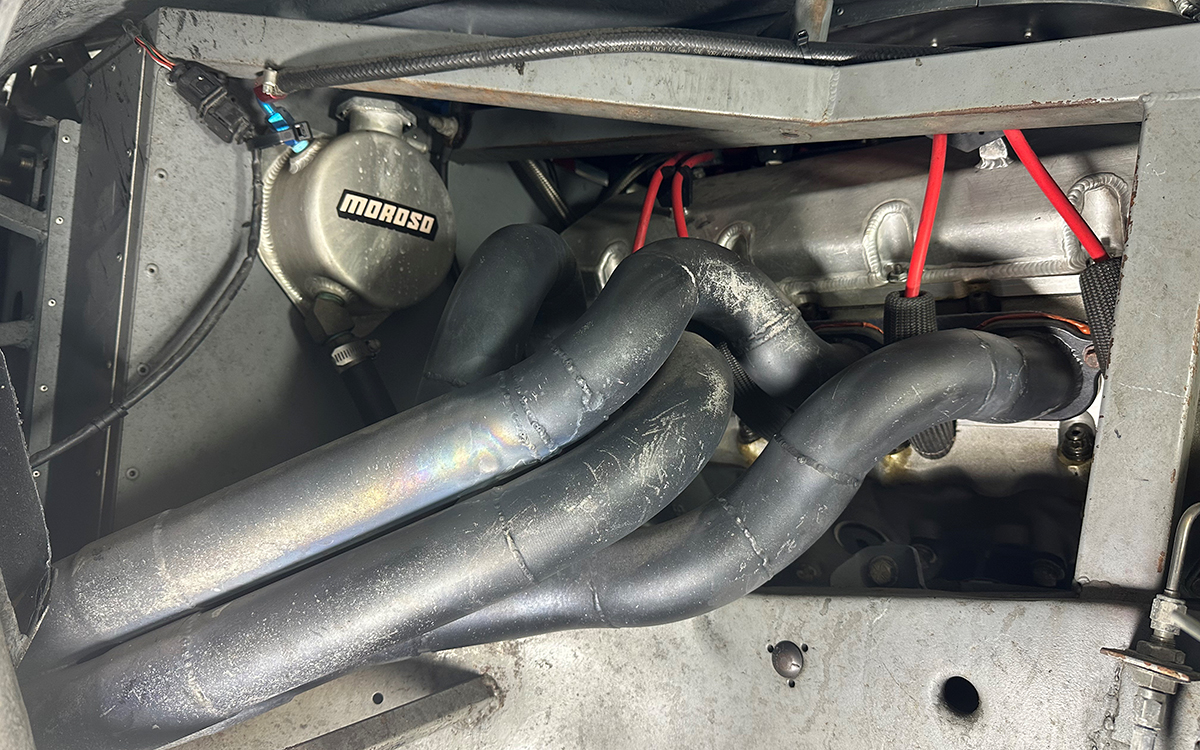

One cost effective power boost can come from properly designed headers, which, of course, we also build in-house. We typically see a 40-horsepower gain on the dyno when upgrading from Hooker style headers to ones we have designed and built.

The headers have to be matched to the specific engine to get the full bang for the buck. There is a science to it, and to make the right headers for your car, we will need to know all about your engine.

Download a copy of our Racing Parts Price List

Want to learn more about Duntov racing parts?

A click will email us and a fast paced dialog can begin. If time is critical and an immediate answer is required, call Alan at (972) 243-3838.