Duntov Classics, LLC manufactures specialty high-performance parts for sale through the website, and markets brake, chassis and suspension parts for the restoration of 1963-1982 Corvettes.

Duntov Classics, LLC is a Dallas, Texas based company involved in the parts, manufacturing, racing and restoring vintage Corvettes.

We specialize in:

- Restomod Manufacturing

- Restorations

- Corvette Street Parts

- Corvette Race Parts

Our Crew

Alan Sevadjian

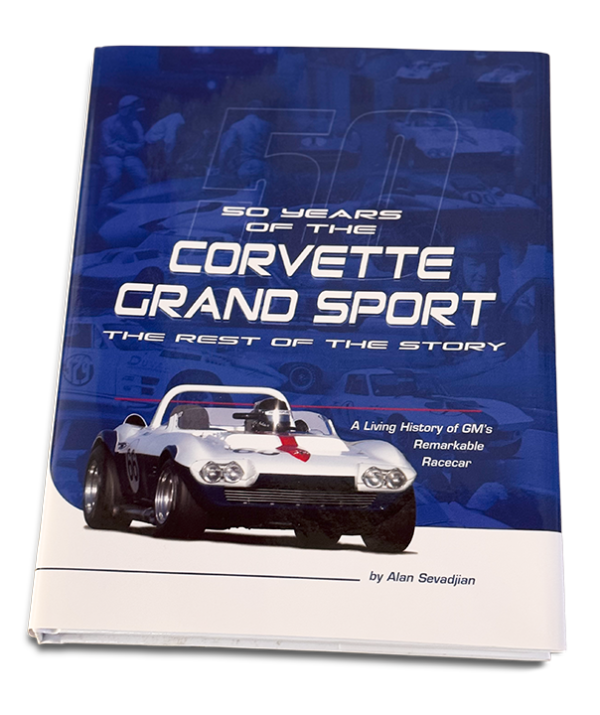

Alan founded this enterprise in 2003 and has been at it ever since, still at the same location. His story is in his latest book, Fifty Years of the Corvette Grand Sport, The Rest of the Story, available here or on Amazon.

Steve Kingman

For the last fifteen years, Steve and wife Tammy owned and operated JB Corvettes of Carrollton, Texas one of the largest Corvette restorations shops in Texas. Duntov acquired JB Corvettes in January 2025, and Steve now runs our shop. Steve’s entire team including his world class paint crew was part of the deal. Steve now runs the shop just as he did at JB Corvettes. We are proud to have Steve and Tammy at Duntov, and look forward to many years together building and restoring the finest Corvettes in the world.

Ian Perrin

Ian answers the phone, and supervises every aspect of our parts department. He is also a master builder of all the components we sell online and install on the cars in our shop, including differentials, suspension components, brake calipers, etc. When you call our shop, you are immediately connected to an expert and not to a salesman.

Richard Morris

Richard ran the Reher & Morrison Racing Engines shop for a decade during which they won four World Pro-Stock Championships. Since 1982, Richard has built all the engines Alan has raced in SCCA and vintage racing, and he continues to build all our customer engines with the same care and fastidious attention to detail that has always been his trademark.

What can our team do for you?

Obviously we specialize in Corvettes. We have other cars in our shop, but they all came from customers for whom we did work on their Corvettes, so we had to take them in!

We started this business as manufacturer of C2 and C3 Corvette chassis restoration parts. As the business grew, we began building cars, our first a tribute car to the one Alan entered at Sebring in 1965, Grand Sport 003. Alan raced the tribute Grand Sport on the 40th anniversary of that first Sebring race. Interest in that car grew and Duntov built several more tribute Grand Sports before GM asked us to build them as authentic continuation Grand Sports, and licensed us to manufacture then for the next ten years.

During the decade of our building Grand Sports, we were tasked to build a run of C1, C2, and C3 Restomods. All these utilized late model Corvette suspension, steering and brakes and an aftermarket frame. We bought frames from all the usual suspects to produce these cars. As the values of these cars skyrocketed in the past few years, we decided to make our own chassis for C2 and C3 Corvettes and hired and engineering firm to design the strongest frame on the market that would accommodate either C2 or C3 bodies and Corvette C7 suspension components. We converted our Grand Sport production to these new frames and have been building them ever since.

As recent market results will attest, restoring a C2 or C3 Corvette is almost as expensive and yields far less at the auctions that a properly built Restomod with all the modern conveniences and the superior ride that comes with the newer generation chassis. For that reason, at the moment, our shop is working on more Restomods than restorations.

Tadge Juechter, Corvette’s Executive Chief Engineer, had this to say about the importance of frame stiffness:

“85 percent of handling is chassis stiffness; everything else – the shocks, springs, sway bars, etc, together adds up to only 15%.”

The Duntov Restomod chassis is the stiffest chassis available anywhere. We tried the rest and found nothing that would deliver the handling of our racecars that have a stock frame, but an additional a full roll cage extending the length of that frame. Our resto rods achieve this stiffness with a much lower center of gravity, and with the advantage of the other 15%; the suspension, shocks, etc, to which Chief Engineer Juechter referred.

Duntov’s service department works almost exclusively on vintage Corvettes. Ours is a full service facility and do everything in house, including air conditioning, alignment, engine and transmission overhauls, chassis and suspension work; everything, including LS conversions on a stock framed C2 and C3 Corvettes.