There are three disc brake design types, each with their own unique advantages and disadvantages. The C2-C3 caliper is a floating piston design. The other two types are floating caliper and floating disc. (The C4 caliper is a floating caliper design, and has O-ring seals.) As you can see, the common factor is that something has to float in all three disc brake types.

Floating piston-type brakes (like the C2-C3 brake system) must address piston knock-back resulting from deflections generated primarily from cornering forces.

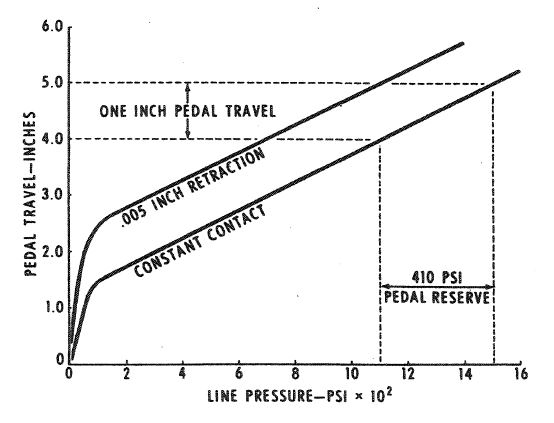

The C2-C3 brake system was designed with a feature known as a ‘constant contact shoe’. The brake pad floats on the surface of the rotor (at a friction loss of approximately .8 HP at 100 MPH) in order to reduce response time and increase pedal pressure reserve. This float is a delicate balance between the lip seal and the spring behind the piston.

“…it has been found to be necessary that the piston be free to follow the disc. This is accomplished with the spring urging the piston toward the disc. This spring force must be light enough to avoid a dragging situation. In turn, the seal friction must be less than the spring force. A lip style seal satisfies this requirement and provides complete freedom from the piston knock-back problem.”

The reduced piston to wall clearance inherent with the O-ring design (when installed in a floating piston caliper), eliminates what Duntov said was necessary. Obviously, the O-ring piston is not free to follow the disc (rotor). The designed-in balance between the lip seal and the piston spring is completely ignored with the aftermarket O-ring pistons. When cornering forces cause spindle deflection, the brake system is put in a bind. As Duntov said, lip seal pistons have the clearances necessary to eliminate this bind and piston knock-back. O-ring sealed pistons do not, and are subject to sticking in the bores unless the caliper in which they are installed is a floating caliper design.